Free House Plan Drawing Software Nz

Artists can use woodworking to create delicate sculptures.

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning.

History [edit]

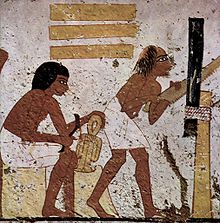

Aboriginal Egyptian woodworking

Along with stone, clay and fauna parts, wood was ane of the first materials worked by early on humans. Microwear analysis of the Mousterian rock tools used past the Neanderthals prove that many were used to work woods. The evolution of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials.

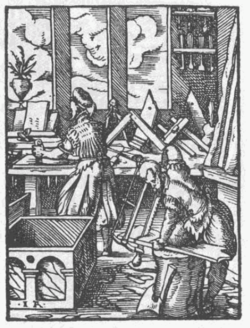

Woodworking shop in Frg in 1568, the worker in front is using a bow saw, the ane in the background is planing.

Amid early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for instance, from the Linear Pottery civilisation wells at Kückhofen and Eythra.

Examples of Bronze Age wood-carving include tree trunks worked into coffins from northern Frg and Kingdom of denmark and wooden folding-chairs. The site of Fellbach-Schmieden in Germany has provided fine examples of wooden animal statues from the Fe Age. Wooden idols from the La Tène menstruation are known from a sanctuary at the source of the Seine in France.

Aboriginal Egypt [edit]

There is significant prove of avant-garde woodworking in ancient Egypt.[one] Woodworking is depicted in many extant ancient Egyptian drawings, and a considerable amount of ancient Egyptian article of furniture (such as stools, chairs, tables, beds, chests) have been preserved. Tombs stand for a big collection of these artifacts and the inner coffins found in the tombs were also fabricated of woods. The metallic used by the Egyptians for woodworking tools was originally copper and somewhen, after 2000 BC bronze equally atomic number 26 working was unknown until much later.[ii]

Commonly used woodworking tools included axes, adzes, chisels, pull saws, and bow drills. Mortise and tenon joints are attested from the earliest Predynastic period. These joints were strengthened using pegs, dowels and leather or cord lashings. Animate being glue came to be used only in the New Kingdom flow.[3] Ancient Egyptians invented the art of veneering and used varnishes for finishing, though the composition of these varnishes is unknown. Although unlike native acacias were used, as was the wood from the local sycamore and tamarisk trees, deforestation in the Nile valley resulted in the need for the importation of wood, notably cedar, but as well Aleppo pine, boxwood and oak, starting from the Second Dynasty.[4]

Ancient Rome [edit]

Woodworking was essential to the Romans. It provided, material for buildings, transportation, tools, and household items. Wood as well provided pipes, dye, waterproofing materials, and energy for oestrus.[5] : 1 Although most examples of Roman woodworking accept been lost,[5] : ii the literary record preserved much of the contemporary knowledge. Vitruvius dedicates an entire affiliate of his De architectura to timber, preserving many details.[6] Pliny, while not a botanist, dedicated six books of his Natural History to trees and woody plants, providing a wealth of information on copse and their uses.[7]

Aboriginal China [edit]

The progenitors of Chinese woodworking are considered to be Lu Ban (魯班) and his married woman Lady Yun, from the Jump and Autumn period (771 to 476 BC). Lu Ban is said to accept introduced the plane, chalk-line, and other tools to Cathay. His teachings were supposedly left behind in the volume Lu Ban Jing (魯班經, "Manuscript of Lu Ban"). Despite this, it is believed that the text was written some 1500 years subsequently his death. This volume is filled largely with descriptions of dimensions for use in building various items such as blossom pots, tables, altars, etc., and as well contains all-encompassing instructions concerning Feng Shui. It mentions almost zero of the intricate glue-less and nail-less joinery for which Chinese furniture was so famous.

Modern day [edit]

With the advances in modern engineering and the demands of manufacture, woodwork as a field has changed. The development of Calculator Numeric Controlled (CNC) Machines, for case, has fabricated us able to mass-produce and reproduce products faster, with less waste product, and frequently more complex in pattern than ever before. CNC wood routers can carve complicated and highly detailed shapes into flat stock, to create signs or art. Rechargeable power tools speed up cosmos of many projects and require much less torso strength than in the by, for example when boring multiple holes. Skilled fine woodworking, however, remains a craft pursued by many. At that place remains demand for hand crafted work such as piece of furniture and arts, however with rate and cost of production, the toll for consumers is much higher.

Materials [edit]

Historically, woodworkers relied upon the woods native to their region, until transportation and trade innovations made more exotic forest available to the craftsman. Woods are typically sorted into three bones types: hardwoods typified by tight grain and derived from broadleaf trees, softwoods from coniferous trees, and human being-made materials such as plywood and MDF.

Hardwoods, botanically known as angiosperms, are deciduous and shed their leaves annually with temperature changes.[viii] Softwoods come from trees botanically known as gymnosperms, which are coniferous, cone-bearing, and stay green twelvemonth round.[viii] Although a general pattern, softwoods are not necessarily always "softer" than hardwoods, and vice versa.[9]

Softwood is most commonly establish in the regions of the world with lower temperatures and is typically less durable, lighter in weight, and more than vulnerable to pests and fungal attacks in comparison to hardwoods. They typically accept a paler color and a more open grain than hardwoods, which contributes to the tendency of felled softwood to compress and smashing equally information technology dries.[ix] Softwoods usually have a lower density, around 432–592 kg/m3, which tin compromise its force.[ix] Density, however, does vary within both softwoods and hardwoods depending on the wood's geographical origin and growth charge per unit. Withal, the lower density of softwoods also allows it to have a greater strength with lighter weight. In the United States, softwoods are typically cheaper and more readily available and accessible.[9] Well-nigh softwoods are suitable for full general construction, especially framing, trim, and terminate piece of work, and carcassing.[x] [9]

Hardwoods are separated into two categories, temperate and tropical hardwoods, depending on their origin. Temperate hardwoods are found in the regions between the tropics and poles, and are of particular involvement to wood workers for their cost-effective aesthetic appeal and sustainable sources.[9] Tropical hardwoods are institute within the equatorial belt, including Africa, Asia, and South America. Hardwoods flaunt a college density, effectually 1041 kg/m3 every bit a result of slower growing rates and is more stable when drying.[9] Every bit a result of its high density, hardwoods are typically heavier than softwoods but can besides be more brittle.[nine] While there are an abundant number of hardwood species, only 200 are common enough and pliable enough to be used for woodworking.[11] Hardwoods accept a broad diverseness of properties, making it easy to observe a hardwood to conform nearly any purpose, only they are especially suitable for outdoor use due to their strength and resilience to rot and decay.[9] The coloring of hardwoods ranges from calorie-free to very nighttime, making it peculiarly versatile for aesthetic purposes. Still, because hardwoods are more closely grained, they are typically harder to work than softwoods. They are besides harder to acquire in the United States and, as a result, are more expensive.[9]

Woodworking manus tools used in class at the Women'southward Woodshop in Minneapolis, Minnesota, USA

Typically furniture such as tables and chairs is made using solid stock from hardwoods due to its strength and resistance to warping.[10] Additionally, they too have a greater variety of grain patterns and colour and have a finish amend which allows the woodworker to exercise a nifty deal of artistic liberty. Hardwoods can exist cut more cleanly and leave less residual on sawblades and other woodworking tools.[ten] Cabinet/fixture makers employ the use of plywood and other homo made panel products. Some furniture, such equally the Windsor chair involve green woodworking, shaping with wood while it contains its natural wet prior to drying.

Common softwoods used for furniture [edit]

Cedar [edit]

Cedars are strong, aromatic softwoods that are capable of enduring outdoor elements, the most common of which is the western cherry cedar. Western red cedar can sustain moisture environments without succumbing to rot, and as a result is commonly used for outdoor projects such as patios, outdoor piece of furniture, and building exteriors. This woods tin exist easily establish at most abode centers for a moderate toll.[12]

Fir [edit]

Within the USA fir, too known every bit Douglas fir, is inexpensive and common at local home centers. It has a feature directly, pronounced grain with a crimson-brown tint. Yet, its grain pattern is relatively plain and it does not stain well, then fir is usually used when the finished production will be painted. While commonly used for edifice, this softwood would besides be suitable for article of furniture-making.[12]

Pine [edit]

White pino, ponderosa, and southern yellowish pine are common species used in furniture-making. White pine and ponderosa are typically used for indoor projects, while Southern yellow pine is recommended for outdoor projects due to its durability.[xiii]

Common hardwoods used for furniture [edit]

Ash [edit]

This hardwood is relatively easy to piece of work with and takes stain well, but its white to light brown colour with a direct grain is visually appealing on its own. However, ash is much more than difficult to observe than other common forest, and will not exist found at the local home centre. Larger lumber yards should have information technology in stock.[12]

Birch [edit]

Whether xanthous or white birch, these hardwoods are stable and easy to work with. Despite this, birch is prone to blotching when stained, so painting birch products is probably best. Birch is hands found at many abode centers and is a relatively cheap hardwood.[12]

Cherry [edit]

Popular and easy to work with, cherry is in high need for its reddish-dark-brown colour and ease of staining and finishing. Carmine probable volition not be at the local habitation center, simply should be at a lumberyard for a somewhat expensive cost.[12] This hardwood is a very common material for furniture, and is resistant to normal wear-and-tear, only it is best for indoor pieces.[14]

Mahogany [edit]

A hardwood, mahogany has a trademark reddish-dark-brown to deep-red tint and is known as "one of the swell article of furniture woods". However, mahogany is non typically grown in sustainable forests, and thus runs a steep price at local lumber yards.[12]

Oak [edit]

With two varieties, cherry and white, oak is known to be easy to work with and relatively strong. Nonetheless, piece of furniture makers oftentimes opt for white oak over blood-red oak for its attractive figure and moisture-resistance.[12] Depending on the kind needed, oak can probably be found at a local home center or a lumberyard for a fleck pricier than other hardwoods.[15] [12] [xiv]

Maple [edit]

With strength, sturdiness, and durability, maple is a common textile for piece of furniture for the bedroom and even cathay cabinets. Maple is moisture-resistant and frequently displays stand-out swirls in the forest grain, an aesthetically pleasing differentiator from other hardwoods. While most usually a lighter colour, maple also can take stains and paint well.[fourteen]

Factors in choosing materials [edit]

There are many factors to consider when deciding what blazon of wood to employ for a project. 1 of the most important is the workability of the forest: the mode in which information technology responds when worked by paw or tools, the quality of the grain, and how information technology responds to adhesives and finishes.[nine] When the workability of wood is high, it offers a lower resistance when cutting and has a diminished blunting effect on tools.[9] Highly workable forest is easier to manipulate into desired forms. If the woods grain is straight and even, information technology will be much easier to create potent and durable glued joints. Additionally, information technology will help protect the wood from splitting when nailed or screwed.[9] Coarse grains crave a lengthy process of filing and rubbing down the grain to produce a smoothen result.[9]

Some other important factor is the durability of the woods, especially in regards to moisture. If the finished projection volition be exposed to moisture (eastward.grand. outdoor projects) or loftier humidity or condensation (east.g. in kitchens or bathrooms), then the wood needs to be specially durable in club to forestall rot. Because of their oily qualities, many tropical hardwoods such as teak and mahogany are popular for such applications.[9]

Woods with good working properties[9] [edit]

Agba (Gossweilerodendron balsamiferum)

Alder (Alnus glutinosa)

Basswood (Tilia americana)

Obeah (Triplochiton scleroxylon)

Pino (Pinus)

Western cedar (Thuja plicata)

Very durable wood[9] [edit]

Teak (Tectona grandis)

Iron (Milicia excelsa)

Jarrah (Eucalyptus marginata)

Chestnut (Castanea)

Oak (Quercus)

Cedar (Thuja)

Woods used for carving [edit]

While many woods can be used for carving, there are some clear favorites, including aspen, basswood, butternut, black walnut, and oak.[xvi] Because it has near no grain and is notably soft, Basswood is particularly pop with beginner carvers. It is used in many lower-toll instruments similar guitars and electric basses.[xvi] Aspen is similarly soft, although slightly harder, and readily available and inexpensive.[xvi] Butternut has a deeper hue than basswood and aspen and has a nice grain that is easy to carve, and thus friendly for beginners. It is besides suitable for furniture.[16] While more expensive that basswood, aspen, and butternut, black walnut is a popular choice for its rich colour and grain.[xvi] Lastly, oak is a potent, sturdy, and versatile wood for etching with a defined grain. Information technology is also a popular woods for article of furniture making.[16]

Common tools [edit]

Each area of woodworking requires a different variation of tools. Power tools and hand tools are both used for woodworking. Many mod woodworkers choose to utilize power tools in their trade for the added ease and to salvage time. However, many choose to still utilise only hand tools for several reasons such as the experience and the added graphic symbol to the piece of work, while some cull to utilize only mitt tools simply for their own enjoyment.

Mitt tools [edit]

Hand tools are classified equally tools that receive power only from the hands that are holding them. The more common modern hand tools are:

- Clamps are used to concur a workpiece while being worked. Clamps vary in all shapes and sizes from small c-clamps to very large bar or strap clamps.[17] A vise is a form of clamp, temporarily or permanently mounted as required. A woodworking vise is a vise specialized to the needs of a woodworker; numerous types have evolved.

- Chisels are tools with a long blade, a cutting border, and a handle. Used for cutting and shaping wood or other materials.[17]

- The claw hammer, which can hammer, pry, and pull nails, is the nigh common hammer used in woodworking.[17]

- A hand plane is used to surface aspects of a workpiece.

- The square is used to mark angles on whatsoever workpiece. An adaptable foursquare as well includes a ruler. A speed square can mark xc and 45-caste fixed angles and any angle between 0 and 90 degrees using its long axis.[17]

- A tape measure out is a retractable or flexible ruler that has measurement increments as small as 1/32" or 1 millimetre.

Power tools [edit]

Power tools are tools that are powered by an external energy such equally a bombardment, motor, or a power cable continued to a wall outlet. The more mutual ability tools are:[17]

- The drill is a tool used to drill a hole or to insert a screw into a workpiece.[17]

- A palm sander is a small powered sander that uses either a vibration or orbital move to move a piece of sand newspaper upon the workpiece making very fine modifications in smoothing your production.[17]

- A chemical compound miter saw, also known as a chop saw is a stationary saw used for making precise cuts across the grain path of a board. These cuts can be at whatever chosen angle that the item saw is capable of.[17]

- A tabular array saw is intended to make long precise cuts along the grain pattern of the board known equally rip cuts. Most table saws offering the selection of a askew rip cutting.[17]

- A thickness planer is used to smooth the surface of a board and make it the exact thickness beyond the unabridged board.[17]

- A jointer is used to produce a flat surface along a lath's length and to create a foursquare (or ninety°) edge betwixt ii adjoining surfaces.[17]

- A band saw[17] is used to brand both irregularly shaped cuts and cuts through material thicker than a tabular array saw tin manage. Information technology is much more robust[18] than the jigsaw or more than fragile coil saw, too regularly used in woodworking.

Notable woodworkers [edit]

- Alvar Aalto

- Norm Abram

- John Boson

- Frank East. Cummings 3

- Henning Engelsen

- Wharton Esherick

- Tage Frid

- Alexander Grabovetskiy

- Greta Hopkinson

- James Krenov

- Mark Lindquist

- Sal Maccarone

- Thomas J. MacDonald

- John Makepeace

- Sam Maloof

- David J. Marks

- Judy Kensley McKie

- George Nakashima

- Jere Osgood

- Alan Peters

- Matthias Pliessnig

- André Jacob Roubo

- Paul Sellers

- Evert Sodergren

- Rosanne Somerson

- Henry O. Studley

- Roy Underhill

- Wendy Maruyama

- Charles H. Hayward

Encounter also [edit]

- Boat building

- Cabinet making

- Carpentry

- Ébéniste

- Fire hardening

- Glossary of woodworking terms

- Green woodworking

- History of construction

- History of woods carving

- Intarsia

- Japanese carpentry

- Lath art

- Luthier

- Millwork

- Marionette

- Marquetry

- Saw pit

- Segmented turning

- Sloyd, a organisation of handicraft-based educational activity

- Stave church

- Studio furniture

- Tack cloth

- Timber framing

- Turning

- Wood carving

- Forest glue

- Forest Inlay

- Woodturning

- Woodworking workbench

References [edit]

- ^ Killen, Geoffrey (1994). Egyptian Woodworking and Piece of furniture. Shire Publications. ISBN0747802394.

- ^ Leospo, Enrichetta (2001), "Woodworking in Ancient Egypt", The Fine art of Woodworking, Turin: Museo Egizio, p. 20

- ^ Leospo, pp. 20–21

- ^ Leospo, pp. 17–19

- ^ a b Ulrich, Roger B. (2008). Roman Woodworking. Yale University Press. ISBN9780300134605. OCLC 192003268.

- ^ Vitruvius. De architectura. one:2.ix.1.

- ^ Pliny (1938). Natural History.

- ^ a b "differences American hardwoods and tropical hardwoods | Hardwood Distributors". www.hardwooddistributors.org . Retrieved 2018-04-16 .

- ^ a b c d e f one thousand h i j thousand l m n o p q Stephen., Corbett (2012). The applied woodworker : a comprehensive footstep-by-step form in working with wood. Freeman, John. Wigston: Southwater. ISBN978-1780192208. OCLC 801605649.

- ^ a b c Korn, Peter (2003). Woodworking basics : mastering the essentials of craftsmanship . Newtown, CT: Taunton Press. ISBN156158620X. OCLC 51810586.

- ^ "Lumber Buying Guide". www.lowes.com . Retrieved 2018-04-sixteen .

- ^ a b c d e f g h "Types of Wood for Woodworking – dummies". dummies . Retrieved 2018-04-sixteen .

- ^ "Working with pine, tips and tricks for success". Wood magazine. Meredith Corporation. March 2003. Retrieved 29 June 2020.

- ^ a b c "The Best Woods for DIY Article of furniture". 2015-06-10. Retrieved 2018-04-16 .

- ^ "Woodworking Nuts". Retrieved 23 March 2015.

- ^ a b c d e f "Tiptop Hardwoods for Carving | Hardwood Distributors". world wide web.hardwooddistributors.org. 2015-05-nineteen. Retrieved 2018-04-16 .

- ^ a b c d e f g h i j k 50 "top xl woodworking tools". 2013-04-13.

- ^ "Difference Between Ring Saw Vs Ringlet Saw". Woodworking Arena. 2020-05-10. Retrieved 2020-07-05 .

References [edit]

- Feirer, John Fifty. (1988). Cabinetmaking and Millwork. Mission Hills California: Glencoe Publishing. ISBN0-02-675950-0.

- Frid, Tage (1979). Tage Frid Teaches Woodworking. Newton, Connecticut: Taunton Press. ISBN0-918804-03-5.

- Joyce, Edward (1987). Encyclopedia of Furniture Making. revised and expanded by Alan Peters. New York: Sterling Publishing Co. ISBN0-8069-6440-v.

- Roubo, André Jacob (1769–1784). The Fine art of the Joiner. Paris: French Academy of Sciences.

Farther reading [edit]

- Naylor, Andrew. A review of woods machining literature with a special focus on sawing. BioRes, April 2013

- History of Woodworking & Aboriginal Carpentry

External links [edit]

- Video about the Zafimaniry peoples in Madagascar.

- Videos nearly woodworking published by Institut für den Wissenschaftlichen Picture. Available in the AV-Portal of the German National Library of Science and Engineering science.

Source: https://en.wikipedia.org/wiki/Woodworking

Enregistrer un commentaire for "Free House Plan Drawing Software Nz"